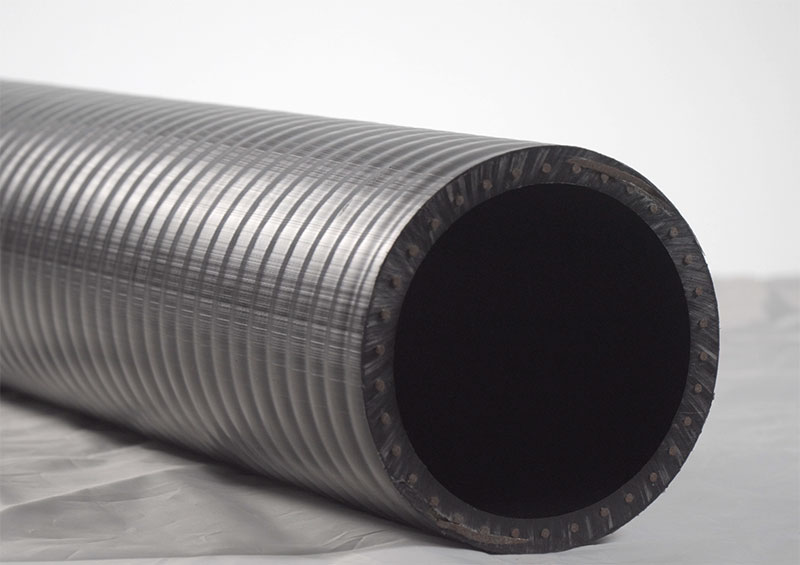

The steel skeleton plastic composite pipe is a composite structural pipe which is continuously produced in a production line by using a steel mesh which is wound and welded to form a reinforcing skeleton, a thermoplastic such as polyethylene as a base, and which are uniformly combined together.

Features

Good creep resistance and long lasting mechanical strength

No rapid cracking will occur

Good impact resistance

Axial with appropriate flexibility

No fouling or waxing on the pipe wall

Non-toxic, non-decomposing, no microbial accumulation

Good temperature resistance

Smooth inner wall and low flow resistance

Easy to locate and track

The ring has sufficient stiffness

Small thermal expansion coefficient

Light weight

Good weather resistance and UV resistance

The inner surface is resistant to highly corrosive media, and the outer surface is adapted to the environment of strong corrosion.

Serialized tubing, fittings and connection structures form a complete and safe piping system

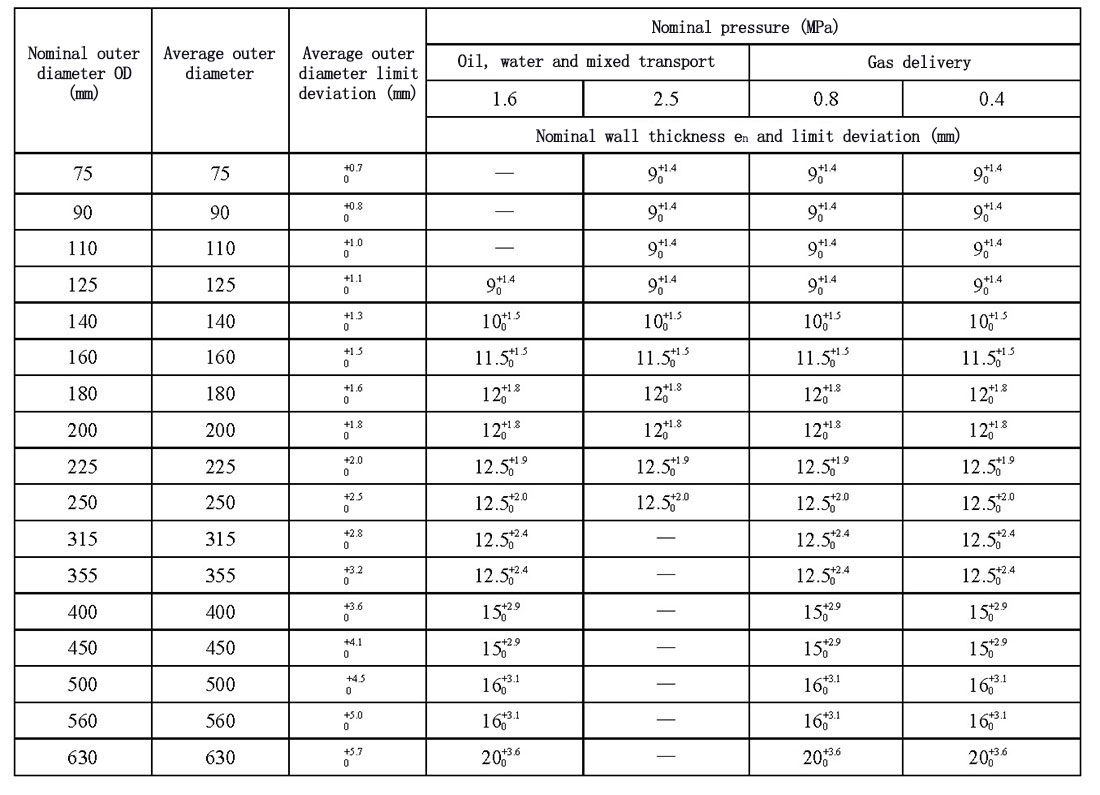

Standard sizes

Executive Standard: Steel skeleton polyethylene plastic composite pipe for oil and gas industry SY/T 6662.1-2012. (This standard also applies to polyethylene-plastic composite pipes for water supply and fire-fighting steel skeletons)

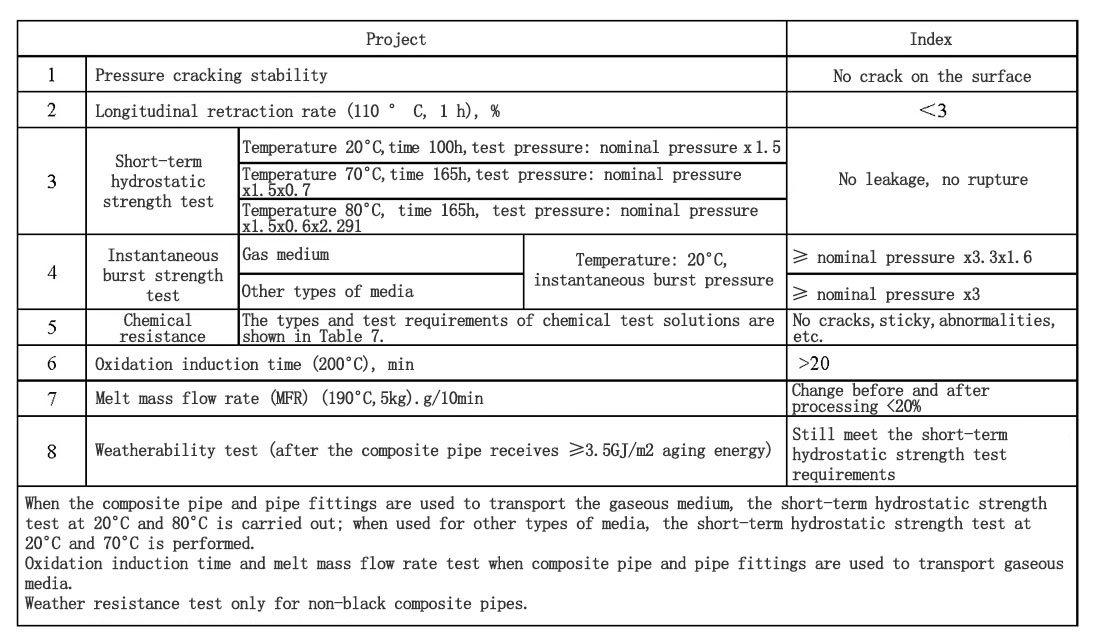

Physical and mechanical properties

Product application range

Chemicals - Industrial piping and discharge pipes for the transport of corrosive media in acid and alkali salt manufacturing, petrochemical, fertilizer, pesticide, pharmaceutical and other industries.

Oilfields - oilfield gathering pipes, sewage pipes, crude oil, refined oil conveying pipes, oil well injection polymer pipes, brine processing pipes, etc. It is especially suitable for medium transportation of sulfur, oil, gas and water.

Municipal construction - urban water supply and drainage, natural gas and gas transportation.

Ships - life pipes and structural piping systems such as sewage pipes, water supply and drainage pipes, ballast water pipes, etc.

Mine - slurry conveying pipe, engineering well pipe, pumping pipe.

Agriculture - used in deep well pipes, filter pipes, irrigation pipes for drylands, culvert drains, etc.

Seawater transport – used for seawater transport in desalination plants, seaside power plants, and seaport cities.