In order to solve the problem of connection and maintenance of PE pipe and PE composite pipe with diameter greater than or equal to 315 (mm), and to reduce the cost, eliminate leakage, improve the ability of the pipeline to resist geological uneven settlement, etc., special invention steel-plastic composite enhanced electric fuse band.

Steel-plastic composite reinforced electric hot melt ribbon structure and characteristics

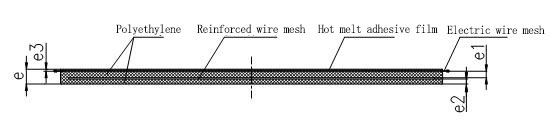

Steel-plastic composite reinforced electric hot-melt belt A kind of electric hot-melt belt which is made by tempering steel wire mesh and polyethylene material after extrusion-forming to form a strip, and then hot-pressing with electric heating screen and hot-melt adhesive film. The basic structure consists of a hot melt adhesive layer-resistive wire mesh layer-polyethylene (PE) layer-wire mesh layer-polyethylene (PE) layer, as shown in the following figure:

Description:

e —— the thickness of the electric heating ribbon;

E1——the minimum distance from the weld surface to the wire mesh;

E2——the minimum distance from the non-welded surface to the wire mesh;

E4——The thickness of the hot melt adhesive layer.

Features:

1-Steel-plastic composite, making full use of the high strength of steel mesh and anti-corrosion of PE, energy saving and environmental protection;

2- Depending on the diameter and pressure level of the connected pipe, one or more layers of steel mesh are used to enhance the processing of the steel-plastic composite reinforced electric hot melt belt;

3- according to the diameter and pressure level of the connected pipeline, one or two layers of steel-plastic composite enhanced electric hot melt belt connection;

4- convenient repair of broken pipes.

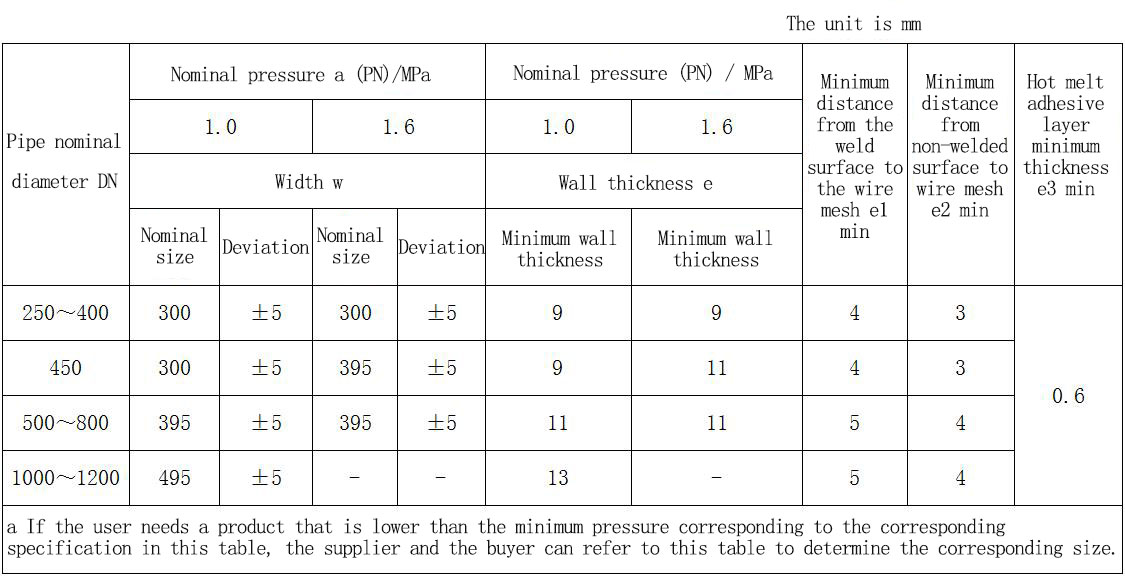

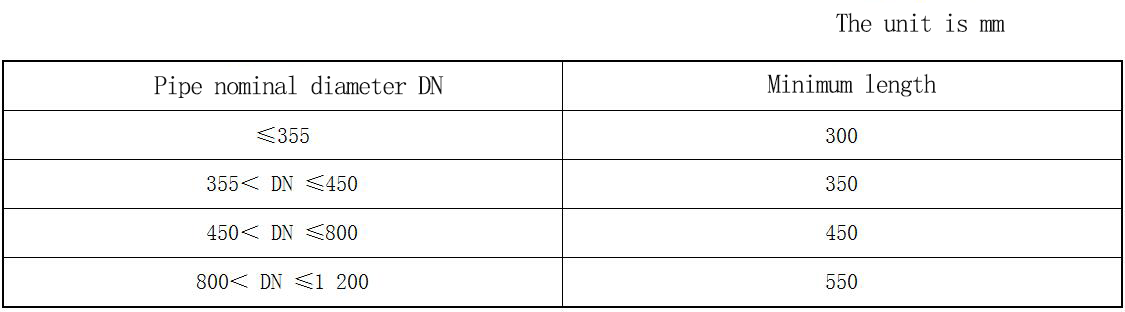

Standard sizes

Steel-plastic composite reinforced electric hot melt belt

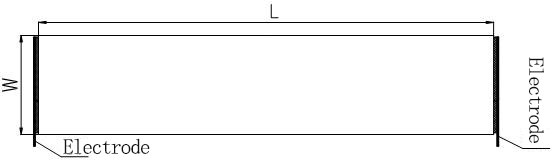

The length of the connection of the electric heating ribbon shall be determined according to the length of the coating determined by the specifications and connection method of the pipe used, and may also be agreed between the supplier and the buyer.

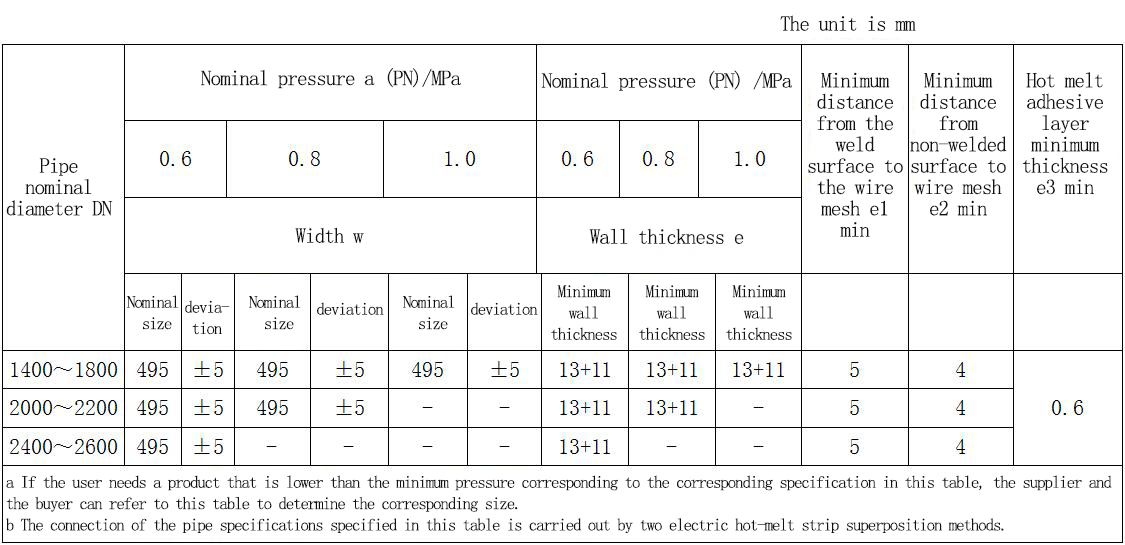

Reinforced steel-plastic composite reinforced electric hot melt belt

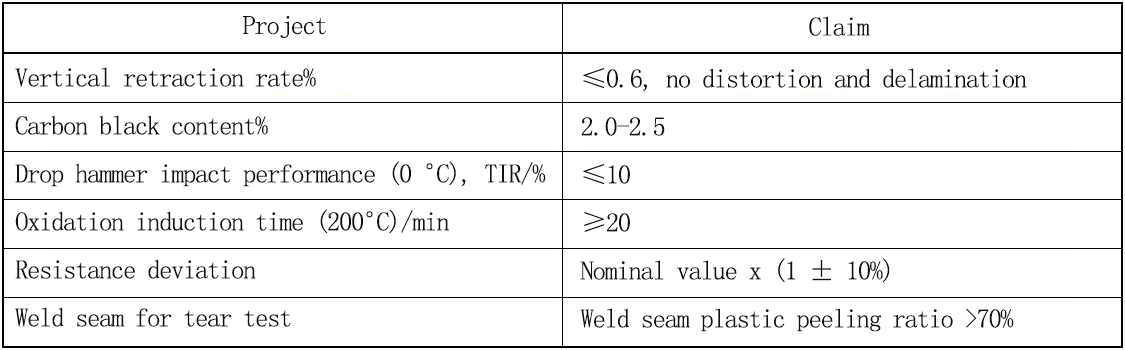

Steel-plastic composite reinforced electric hot melt belt technical requirements

Steel-plastic composite reinforced electric hot melt belt application

It is suitable for pipe connection of polyethylene type such as urban water source pipeline, seawater desalination pipeline, municipal water supply pipeline, pressure sewage pipeline and water conservancy project.

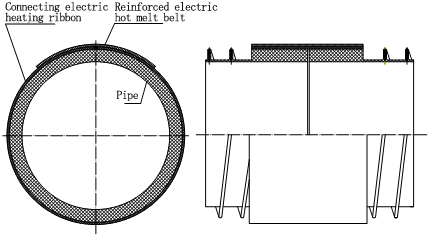

Pipe external welding connection

The way in which the hot melt belt is connected to the pipe from the outer surface of the pipe

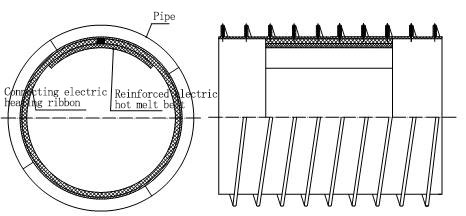

Pipe welding connection

After the pipe is welded by the electric heating ribbon, the gap formed between the ends of the electric heating ribbon is filled and filled by means of extrusion filling welding, and then welded by the reinforcing electric hot melt belt.

Executive standard

"Steel-plastic composite enhanced electric hot melt belt" Q/HBSDW 101—2017