PE is a polyethylene plastic, the most basic kind of plastic, plastic bags, cling film, etc. are PE, HDPE is a high crystallinity, non-polar thermoplastic resin. The original HDPE has a milky white appearance and a semi-transparent shape in a thin section. PE has excellent resistance to most of the characteristics of living and industrial chemicals.

PE pipe welding, PE pipe butt welds, this method provides the highest reliability and diameter within the range and pressure process: the end of the heated pipe, using a tool called "contact mirroring and temperature" under the definition of "mirror ". The ends are quickly contacted and kept under pressure during the cooling process.

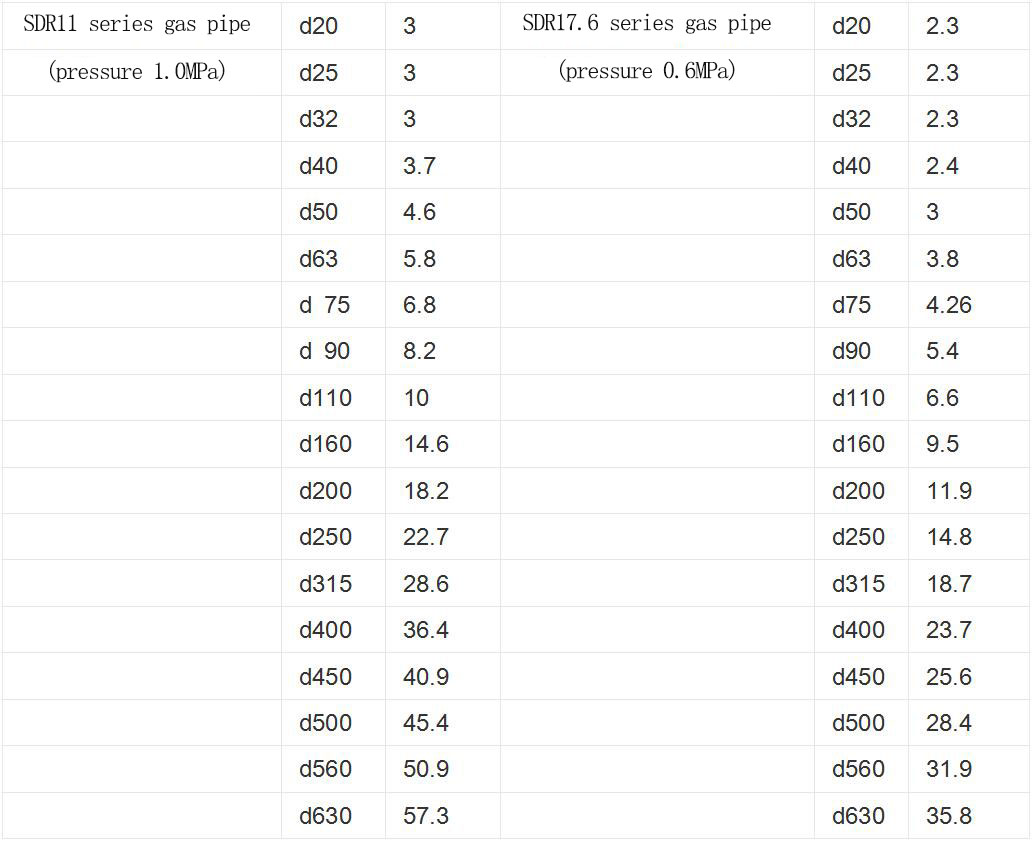

PE pipes are medium density polyethylene pipes and high density polyethylene pipes. According to the wall thickness, it is divided into SDR11 and SDR17.6 series. The former is suitable for conveying gaseous artificial gas, natural gas, liquefied petroleum gas, and the latter is mainly used for conveying natural gas. Compared with steel pipes, the construction process is simple, has certain flexibility, and more importantly, it is not used for anti-corrosion treatment, which will save a lot of processes. The disadvantage is that the instrument is not as good as the steel pipe. In the construction, special attention is paid to the safe spacing of the heating, and it cannot be exposed to the sunlight in the air, and it is sensitive to chemicals and prevents the leakage of the sewage pipe.

PE pipe for water supply is a replacement for traditional steel pipe and PVC drinking water pipe.

The water supply pipe must withstand a certain pressure, usually a PE resin with a large molecular weight and good mechanical properties, such as HDPE resin. The LDPE resin has low tensile strength, poor pressure resistance, poor rigidity, poor dimensional stability during molding, and difficulty in connection, and is not suitable as a material for the water supply pressure pipe. However, due to its high health indicators, PE, especially HDPE resin, has become a common material for the production of drinking water pipes. HDPE resin has a small melt viscosity, good fluidity and easy processing, so the range of its melt index is also wide, and the MI is usually between 0.3 and 3 g/10 min.

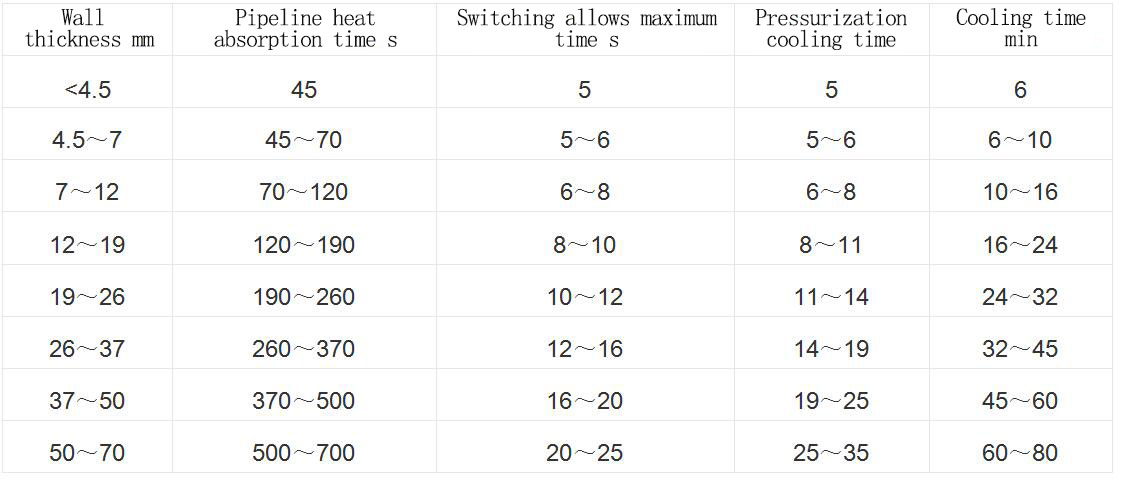

According to the material of the pipe, adding the value in each time range is the welding time required for each port. The cooling time of the welded nozzle is generally 10-12 times the wall thickness.

According to the production method of the pipe fittings: injection pipe fittings, welded pipe fittings.

According to the construction method and use classification: electric hot melt pipe fittings, hot melt butt fittings, socket fittings, steel-plastic conversion joints.

According to engineering habits: sleeve, elbow, tee, saddle tee, variable diameter, end plug, flange, steel-plastic conversion.

According to the PE pipe, the pressure is divided into 0.6MPa, 0.8MPa, 1.0MPa, 1.25MPa, 1.6MPa, and MPa is the pressure unit. For example, 0.6MPa means 6kg.

According to the diameter of the PE pipe, it can be roughly divided into: 20, 25, 32, 40, 50, 63, 75, 90, 110, 125, 160, 180, 200, 225, 250, 280, 315, 355, 400. 450,500,560,630,710,800,900,1000,1200, the unit is mm or mm, PE pipe diameter refers to the outer diameter, corresponding to the different pressure levels, the wall thickness of the pipe is also different .

PE specification

Features

■ Good hygienic performance: PE pipe processing does not add heavy metal salt stabilizer, the material is non-toxic, no fouling layer, no bacteria, and it solves the secondary pollution of urban drinking water.

■ Good corrosion resistance: It can withstand a variety of chemical mediations except for a few strong oxidants; no electrochemical corrosion.

■ Long service life: PE pipes can be safely used for more than 50 years under rated temperature and pressure conditions.

■ Better impact resistance: PE pipe has good toughness and high impact strength. Heavy objects directly press through the pipe and will not cause pipe rupture.