Steel mesh reinforced polyethylene composite wear-resistant pipe

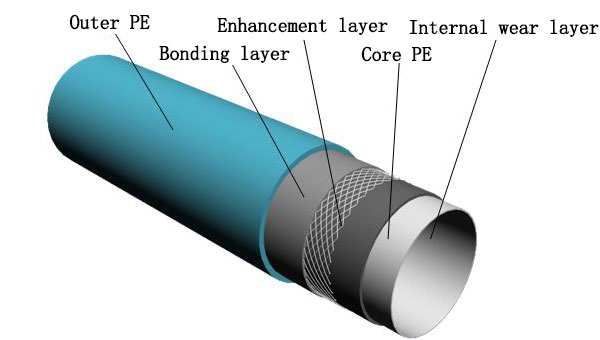

The steel mesh reinforced polyethylene composite wear-resistant pipe is a composite pipe which is a co-extruded inner layer of a polyolefin thermoplastic elastomer as an inner layer and a steel mesh reinforced polyethylene composite pipe. The pipe not only maintains the excellent physical and mechanical properties of the steel mesh reinforced polyethylene composite pipe, but also has good wear resistance.

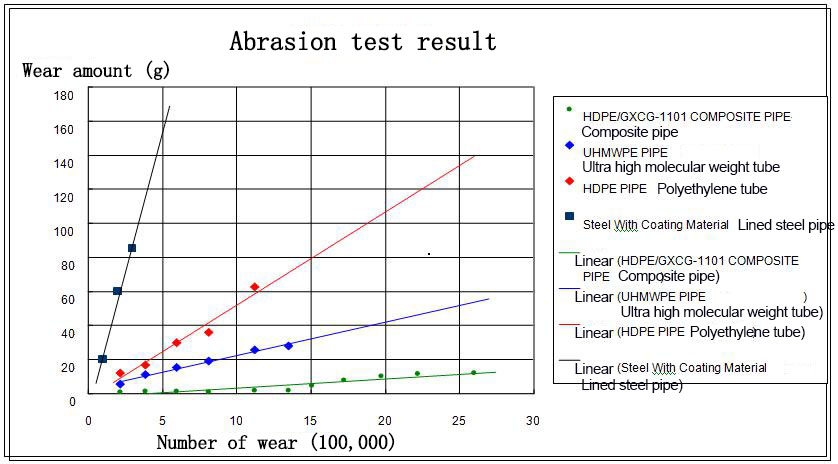

Through a series of tests such as the swing wear test and the slurry loop abrasion test, the steel mesh reinforced polyethylene composite wear-resistant tube has excellent wear resistance, and the wear-resistant tube widely used in the market, such as ultra-high molecular weight polyethylene tube. Compared with lining steel pipes, the wear resistance is more excellent.

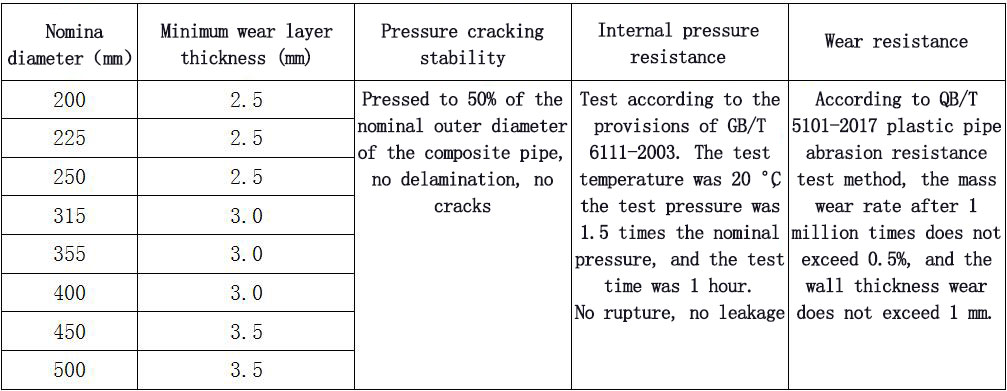

The material, size, deviation and pressure grade of the base pipe (excluding wear-resistant layer) of steel mesh reinforced polyethylene composite wear-resistant pipe shall comply with the provisions of GB/T 32439-2015, wear-resistant layer thickness, physical mechanics and wear resistance. The requirements are as shown in the following table:

Application field

Chemical industry: such as coal powder, silicon powder, salt slurry, alkali slurry and other solid-liquid mixture conveying pipeline;

Electricity: such as the process pipeline for removing ash, slag, powder feeding, powder returning and desulfurization in thermal power plants;

Metallurgy: such as concentrate slurry, tailings long-distance pipeline transportation, mineral processing plant minerals and solvent process pipelines;

Cement: such as raw slurry transport, pulverized coal conveying, hoist cutting, finished cement pneumatic conveying and loading, concrete conveying pipeline of rotary kiln wet production line;

Grain: Wind pipes such as wheat, grain, and chaff.