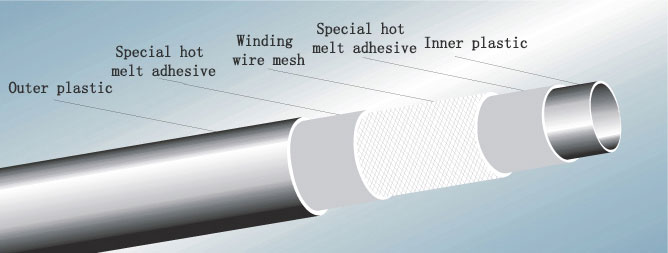

The steel mesh skeleton plastic composite pipe (referred to as a composite pipe) is a reinforcement body formed by spirally forming a high-strength steel wire. The high-density polyethylene (HDPE) is used as a base, and the wire mesh skeleton is tightly joined to the inner and outer layers of high-density polyethylene by a high-performance adhesive resin layer. The bonding resin is a high-performance bonding material and belongs to the HDPE modified material. It can be completely melted under the heating condition of HDPE, and at the same time, its polar bond has strong bonding property with steel wire. Due to the use of the bonding resin, the problem of no connection factor between steel and polyethylene has been successfully solved, and the composite effect is more excellent.

Composite pipe structure

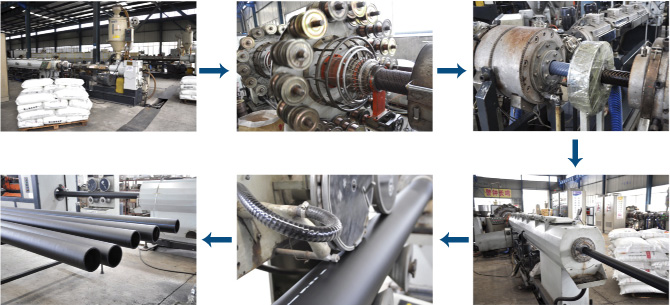

Production Process

Features

● It has more strength, rigidity and impact resistance than ordinary plastic pipes, similar to the low linear expansion coefficient and creep resistance of steel pipes.

● Double-sided anti-corrosion, with the same anti-corrosion performance as plastic tubes, high temperature and corrosion resistance, and low thermal conductivity.

●The structure is excellent, the reinforcing skeleton of the pipe and the inner and outer plastics are mutually contained as one whole, and there is no worry about the peeling of the inner and outer plastics and the reinforcing body.

● The composite of steel and plastic materials is uniform and reliable, which overcomes the rapid cracking phenomenon of PE pipes. Since the two materials of steel and plastic are structural composite forms, there is no rapid stress cracking phenomenon that plastic pipes are difficult to overcome.

●The inner wall is smooth, no scaling, small flow resistance, and the pipe head loss is 30% lower than that of the steel pipe.

● Pipes with different pressure levels can be produced by adjusting the wire diameter and the number of wires.

● Light weight, easy to install, the pipe connection uses electric hot-melt joints, strong axial tensile resistance, mature and reliable connection technology, complete development of pipe fittings and specifications, and can be connected with various other pipes, valves and equipment.

●The overall reliability of the pipe is high. Under normal use, the service life can reach 50 years. The overall cost performance is excellent, and it is hygienic and non-toxic. It is an ideal substitute for steel pipe, ducted pipe and pure plastic pipe.

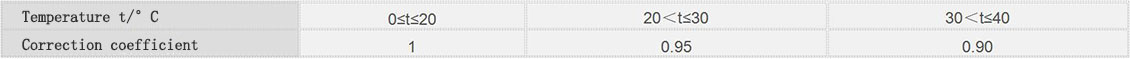

Temperature pressure correction factor value

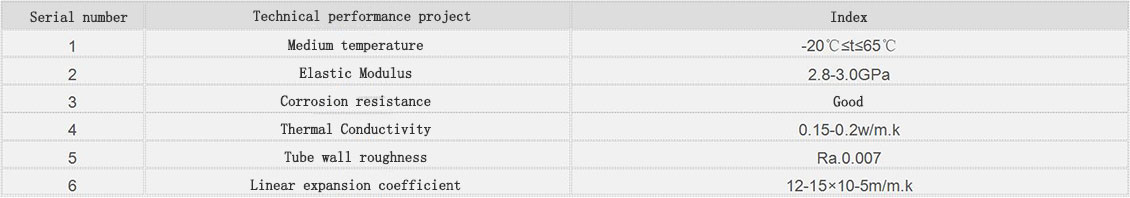

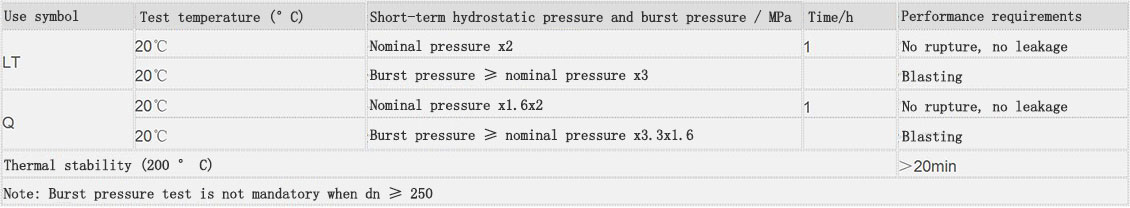

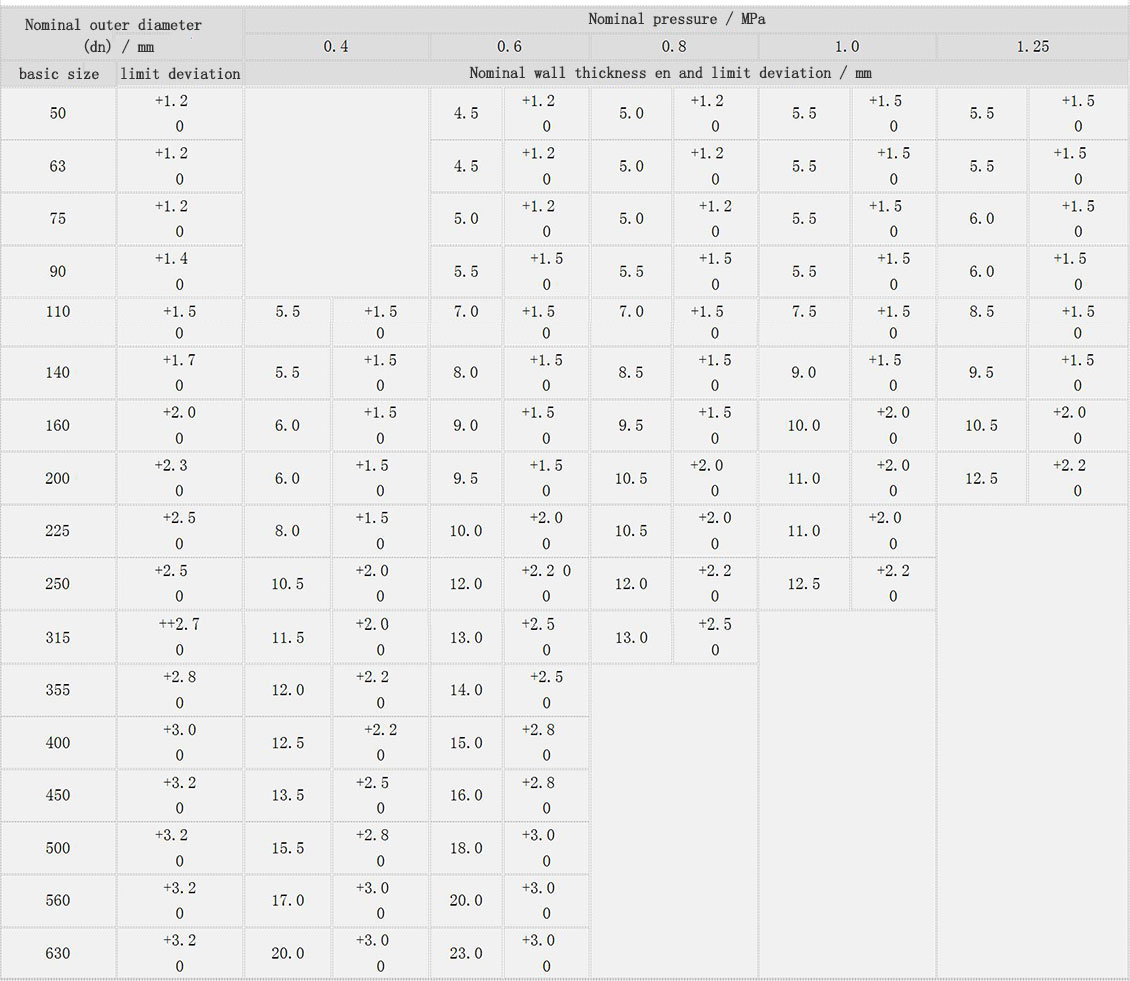

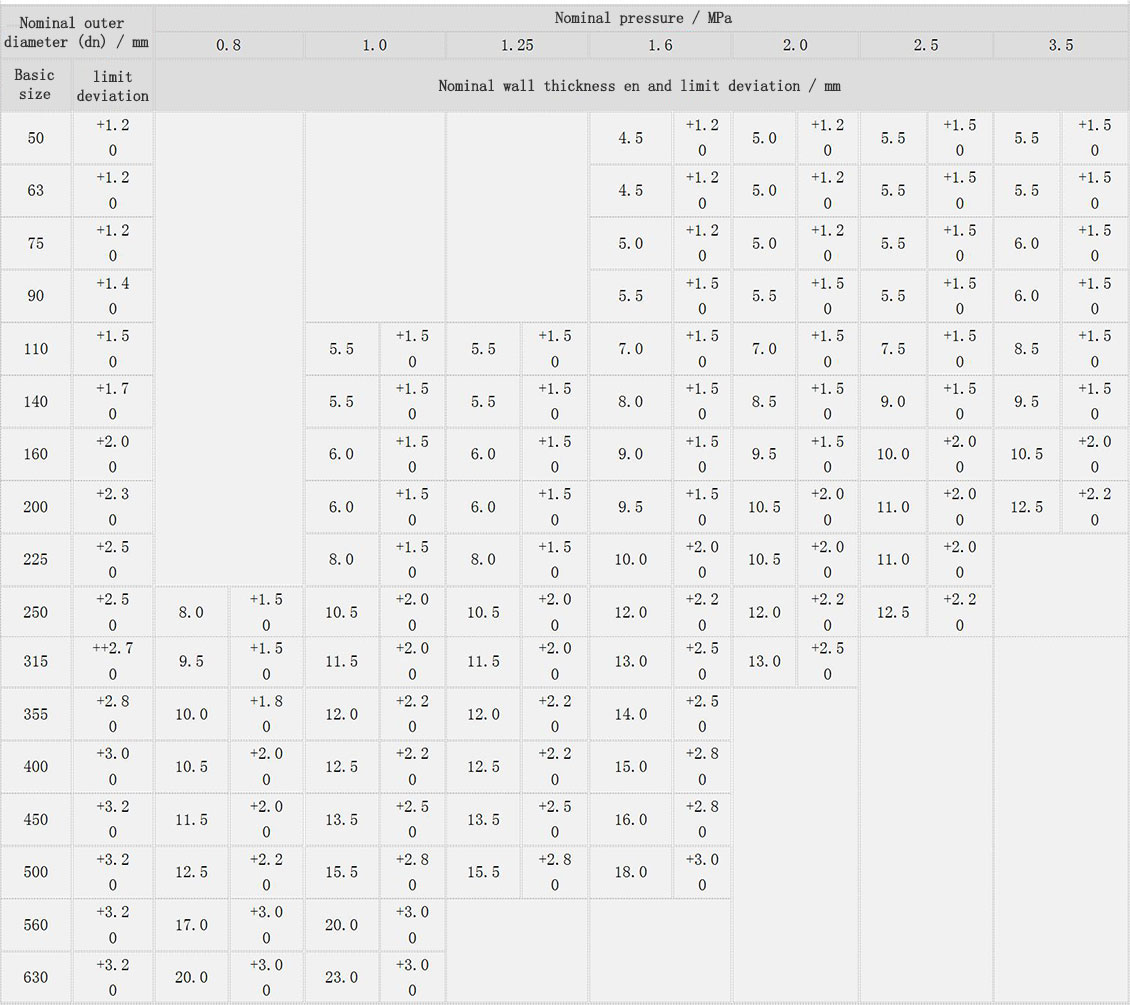

Main technical performance

Physical and mechanical properties

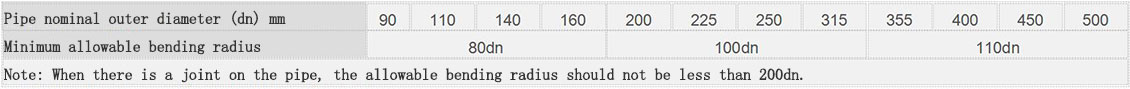

Bending radius of the pipe

Skills requirement

The color is generally black, and can also be determined according to the supply and demand side.

The inner and outer surfaces of the pipe should be smooth and smooth, allowing micro-pits and protrusions with natural shrinkage. Bubbles, cracks, discoloration lines and obvious wounds are not allowed, and the ends of the pipe are cut flat.

Steel mesh skeleton polyethylene composite pipe for underground coal mine

"Tianjian" coal mine wire mesh skeleton polyethylene pipe is a winding steel wire mesh as the middle layer, the inner and outer layers are fire-retardant anti-static special polyethylene plastic used in coal mine underground, using special hot melt adhesive, through extrusion molding method Composite pipe (the structure of the pipe is shown in the figure).

Classification, model and specifications

1, classification

The steel mesh skeleton polyethylene pipe used in coal mine underground can be divided into gas universal pipe (KMQ) and liquid universal pipe (KML). The gas universal pipe CKMQ) can be used for coal mine underground positive pressure ventilation, negative pressure ventilation, gas drainage, etc.: Liquid general purpose pipe (KML) can be used for coal mine underground water supply drainage, shotcreting and so on.

2, specifications and models

Table 1 gas universal pipe size

Table 2 Liquid general pipe size

Double-layer two-color steel mesh skeleton polyethylene composite pipe

Double-layer two-color steel mesh skeleton polyethylene composite pipe, also called steel mesh skeleton polyethylene two-color composite pipe, is a mesh-shaped skeleton formed by spiral winding of high-strength steel wire, and is made of high-density polyethylene (HDPE) as a matrix. The high-performance adhesive resin layer tightly bonds the wire mesh skeleton to the inner and outer high-density polyethylene. The bonding resin is a high-performance bonding material and belongs to the HDPE modified material. It can be completely melted under the heating condition of HDPE. At the same time, its polar bond has strong bonding property with steel due to bonding. The use of the resin successfully solves the problem of no connection factor between steel and HDPE, and has a better composite effect. The biggest difference between it and the ordinary steel mesh skeleton plastic composite pipe is that no recycled raw materials are added, and the inner wall is white and the outer wall is black.