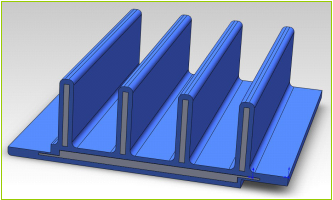

Recently, our company "Tianjian" brand multi-reinforced steel-plastic composite pressure pipe has been commissioned and officially put into operation. The pipeline is based on the existing steel skeleton plastic composite pipe and steel belt reinforced plastic drainage pipe technology, using metal plastic. New steel-plastic composite pressure conveying pipeline developed by technology such as composite molding, steel-plastic composite structure design and strip winding welding.

Followed by Hubei steel-plastic composite pipe manufacturers have always understood the advantages of this pipe:

1. The pipe has excellent internal and external pressure resistance and long-term strength stability.

2, electric heat welding connection technology is simple and reliable, 100% no leakage, will not cause waste of transporting liquid resources.

3, resistance to internal and external corrosion, long service life.

4, the wear resistance is very strong.

5. The inner wall is relatively smooth, the conveying resistance is small, the hydraulic characteristics are good, and the conveying capacity is high.

6, safe and non-toxic, energy saving and environmental protection.

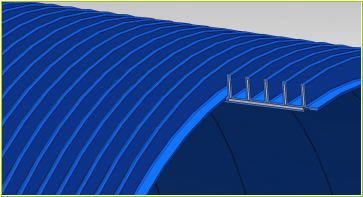

7. The pipe structure has good stability and belongs to the flexible system, which can be suitable for local quality conditions.

8, light weight, low construction and installation costs, the overall cost of the project is low, cost-effective, has a strong market competitiveness.

In the range of medium and small diameter, medium and low pressure and normal temperature buried water plastic pipelines, this pipeline is an ideal option to reduce the construction cost, and can be widely used in municipal pipe network, agricultural water conservancy pipe network, township, factory, mine water supply, etc. market.

In the pressure sewage pipeline market, the pipeline is highly competitive.

In point-to-point water diversion projects such as seawater desalination, urban water diversion, water resource allocation, and large-scale industrial projects, the large-diameter series of products can be used as a new option for cost-effectiveness.