"Tianjian" brand multi-reinforced steel-plastic composite pressure pipe is based on the existing steel skeleton plastic composite pipe and steel belt reinforced plastic drainage pipe technology, using metal plastic composite forming, steel-plastic composite structure design and strip winding welding A new steel-plastic composite pressure transmission pipeline developed by molding and other technologies. The pipeline system combines structural wall technology, multi-wall technology and steel-plastic composite technology, which not only effectively improves the radial strength and ring stiffness of the pipe, but also reduces the amount of plastic used, thereby saving production costs.

Strip and tube structure

According to different calibers, the pipe is made of one or two layers of steel-plastic composite strips spirally wound and welded. The outer strip consists of a strip and vertical reinforcing ribs that are perpendicular to the strip surface and integral with the strip. The reinforcing rib is composited with a reinforced steel strip, and a multi-layer reinforced steel mesh is composited in the strip according to different strength requirements. The inner layer strip is in the form of a thick strip, which is as wide as the outer strip and has a multi-layer reinforced wire mesh interlayer. When the pipe is composed of a single layer of tape, the outer layer of the material is spirally wound, and the edge is in the form of a lap joint, and a sufficient overlap width is designed to ensure sufficient axial strength of the pipe. When the tube is composed of a double-layer strip, the spiral wound seams of the inner and outer strips are staggered to obtain maximum axial strength of the tube. The lap joint of the single-layer strip and the fit between the inner and outer strips are all welded by the same type of plastic continuous extrusion.

Pipe Specifications and Pressure / Ring Stiffness Series

| Nominal diameter dn,mm | Nominal pressure PN, MPa | Ring stiffness SN, KN/m2 | ||

| 0.6 | 0.8 | 1.0 | ||

| Minimum wall thickness en, mm | Minimum wall thickness en, mm | Minimum wall thickness en, mm | ||

| 315 | 6 | 6 | ≥12.5 | |

| 355 | 6 | 6 | ≥12.5 | |

| 400 | 8 | 8 | ≥12.5 | |

| 450 | 8 | 8 | ≥12.5 | |

| 500 | 8 | 8 | ≥12.5 | |

| 560 | 8 | 8 | ≥12.5 | |

| 630 | 8 | 8 | ≥12.5 | |

| 710 | 8 | 8 | ≥12.5 | |

| 800 | 10 | 10 | ≥12.5 | |

| 1000 | 10 | 10 | ≥12.5 | |

| 1200 | 11 | 11 | ≥12.5 | |

| 1500 | 22 | 22 | 22 | ≥10 |

| 1600 | 22 | 22 | 22 | ≥10 |

| 1800 | 22 | 22 | ≥10 | |

| 2000 | 22 | 22 | ≥10 | |

| 2200 | 22 | 22 | ≥10 | |

Description: This kind of pipe structure can achieve a good series expansion by adjusting the structural parameters of steel mesh and steel strip, thus obtaining a series of products with different pressure levels.

Temperature correction factor for nominal pressure

When the pipe is transported at a medium above 20 °C, the maximum allowable pressure can be determined by multiplying the correction factor shown in the table below by the nominal pressure.

| Temperature t/°C | 0<t≤20 | 30 | 40 | 50 | 60 |

| Nominal pressure correction factor | 1.00 | 0.95 | 0.90 | 0.80 | 0.70 |

Pipe characteristics and advantages

The pipe has excellent internal and external pressure resistance and long-term strength stability.

The multi-reinforced steel-plastic composite pressure pipe mechanism adopts two kinds of skeleton reinforcing phases of steel strip and steel mesh in the pipe wall to improve the ring stiffness of the plastic pipe against external pressure and the ring stress against internal pressure. Specifically, the profiled steel-plastic composite strip is used, that is, the tensile strength of the molded plastic bottom tube is improved by using one or more layers of metal mesh and plastic composite, and a plurality of steel strips and plastic shaped sheets are combined to form a bottom tube sheet. Vertical steel plate ribs. After the specially designed reinforced composite strip is wound, welded and continuously formed into a tube, the steel-plastic composite rib outside the tube can improve the external pressure resistance of the pipeline to increase the rigidity of the pipeline loop, and the reinforcing steel mesh in the bottom tube sheet plastic can be improved. The internal pressure resistance of the pipe greatly increases the pressure on the pipe. The reasonable structure of double reinforcement of steel strip and steel mesh is adopted, so that the strength and ring stiffness of the pipe can meet the requirements of engineering application, transportation, storage and construction.

Electrothermal fusion welding connection technology is simple and reliable, 100% no leakage, no waste of transporting liquid resources

The multi-reinforced steel-plastic composite pressure pipe connection adopts the mature leak-free steel-plastic composite electric hot-melt belt heating fusion welding technology for convenient and quick connection, thereby achieving 100% sealing, zero interface leakage rate, completely isolating the liquid in the pipeline. Leaked to the outside world. This is not possible with some other types of pipes such as ductile iron pipes and PCCP pipes. Today, as water resources become increasingly tense, this advantage of multiple reinforced steel-plastic composite pressure pipes has a special era significance.

Resistance to internal and external corrosion, long service life

The raw materials of the multi-reinforced steel-plastic composite pressure pipe are polyethylene, steel strip and steel mesh for the pipe, and the steel strip and the steel mesh are completely covered in the polyethylene. Pipe-specific polyethylene has stable chemical properties and is resistant to almost all diluted acids, bases, alcohols, oils and gasoline, as well as other corrosive media and environments. Therefore, the pipe can be buried under almost any conditions of use, including Harsh environments such as high alkali, sewage and other corrosive environments.

International standards stipulate that under normal use, the service life of polyethylene pipes is at least 50 years, and the multi-reinforced steel-plastic composite pressure pipes do not have creep problems, so their service life is much higher than that of pure plastic pipes, and is much larger than reinforced concrete. Cast iron or ordinary steel pipe. The multi-reinforced steel-plastic composite pressure pipe has the characteristics of wear resistance, corrosion resistance and good joint sealing, which makes its service life more than 100 years. The average life of reinforced concrete pipes, cast iron or ordinary steel pipes under normal working conditions is relatively low.

Extremely strong wear resistance

Experiments have shown that pipe-grade polyethylene has excellent wear resistance, and its wear resistance is 3 to 5 times better than that of ordinary steel pipes at a flow rate of 15 ft/s.

The inner wall is relatively smooth, the conveying resistance is small, the hydraulic characteristics are good, and the conveying capacity is high.

The inner wall of the multi-reinforced steel-plastic composite pressure pipe is very smooth, the roughness is small, and since the plastic material has strong anti-adhesion property, the pipe is not easy to scale, and the deposit cannot adhere, so the resistance loss when the fluid flows is small. It has been proved that under the same pressure, the required flow rate can be achieved by using a multi-reinforced steel-plastic composite pressure pipe with a smaller diameter; at the same diameter, a multi-reinforced steel-plastic composite pressure pipe can increase the liquid flow rate.

Safe and non-toxic

The pipe plastic is made of polyethylene resin that can reach the hygienic level of drinking water transportation. It is suitable for cleaning the water supply pipeline and will not cause secondary pollution to the transportation medium.

Flexible system, good avoidance of disasters

In the multi-reinforced steel-plastic composite pressure pipe, the high-density polyethylene and the steel strip have good flexibility, and the pipe connection adopts the electric hot-melt strip welding method to make it connect into a flexible whole, and the whole pipeline has greater flexibility. Sex, even if soil subsidence or even earthquake occurs, the pipeline will not break, and the medium can still be transported normally, and the secondary disaster of earthquake will not be expanded. However, due to the excessive rigidity of the glass steel pipe, the cement pipe, the cast iron pipe or the polyvinyl chloride pipe, the uneven deformation of the pipe base cannot be withstood, and it is inevitable that the crack occurs during the earthquake.

Light weight, low construction and installation costs

The multi-reinforced steel-plastic composite pressure pipe is reinforced with steel strip and steel mesh, with light weight and low relative density, while the concrete density is 2400kg/m3 and the cast iron density is 7850kg/m3. It can be seen that it is easier to transport and install on site than reinforced concrete pipes, cast iron pipes and other structural wall type pure plastic pipes, which can shorten the construction period and greatly save construction costs.

Raw material consumption cost is lower than pure plastic or other structural wall plastic pressure pipe

In the multi-reinforced steel-plastic composite pressure pipe, the pipe strength is mainly borne by the steel strip and the steel mesh due to the use of the reinforced steel strip and the steel mesh skeleton, and the elastic modulus of the steel is 235 times that of the plastic, therefore, the diameter of the pipeline The strength and hoop stiffness are enhanced, and even if the pipe diameter is large, it can bear the internal pressure caused by the relatively strong conveying medium and the external pressure caused by the soil and traffic load. Therefore, the wall thickness of the pipe can be greatly reduced, thereby greatly saving the cost of raw materials.

Compared with the 1990s, oil prices have almost tripled, and on February 7, 2012, it reached a record high of more than 136 US dollars a barrel, and oil prices have an irreversible trend of continuing to rise, leading to petrochemicals. The prices of plastics such as polyvinyl chloride and polyethylene in downstream products are also high. In this situation, the raw material cost advantage of multiple reinforced steel-plastic composite pressure pipes will become more prominent.

The overall cost of the project is low, cost-effective, and has strong market competitiveness.

Considering the cost savings of raw materials, transportation and installation, the comprehensive cost of the medium and small diameter (dn200-dn1200mm) multi-reinforced steel-plastic composite pressure pipeline project is lower than any existing pure plastic pipe, plastic composite pipe, structural wall plastic pipe or cast iron pipe. In addition, due to the low internal roughness of the plastic pipe, and the plastic pipe of the same diameter as the reinforced concrete pipe can transport a larger medium flow rate (about 30% higher), the comprehensive cost of the multi-reinforced steel-plastic composite pressure pipe is also lower than that of the steel bar. Concrete pipe. The large-scale products not only have low overall cost of construction, but also have the advantage of filling the market gap.

Good structural stability of the pipe

The pipe will not be deformed or ovalized during loading, unloading, storage and transportation, and the installation is easy and the connection is reliable.

Energy saving and environmental protection

The multi-reinforced steel-plastic composite pressure pipe production process has no waste gas, waste water and waste, and is zero-emission, and has no pollution to the environment. Secondly, the plastic in the waste plastic pipe can be re-crushed and granulated, recycled and reused; the scrap steel belt and steel mesh can be used as high-quality raw materials for electric steelmaking. In addition, since the inner wall of the pipe is smooth, the conveying resistance is small, and no scale is formed, so the running cost is low and the energy is saved. The multi-reinforced steel-plastic composite pressure pipe will be the representative of the latest generation of energy-saving and environmentally friendly products.

Pipe connection structure

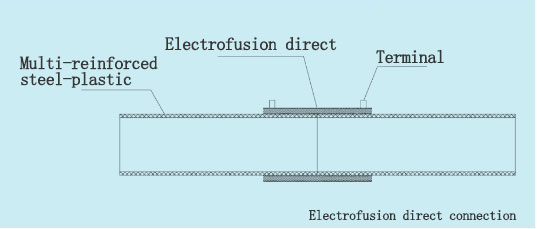

The multi-reinforced steel-plastic composite pressure pipe mainly has two methods of electrofusion direct connection and steel-plastic composite pipe electrothermal fusion zone connection.

Electrofusion direct connection

Steel-plastic composite electric hot melt belt connection

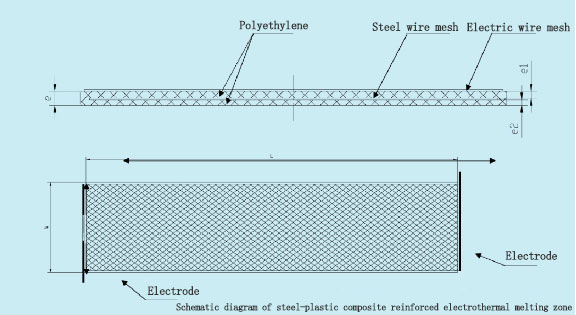

The steel-plastic composite electric hot-melt belt connection can be applied to all kinds of pipe connections. The steel-plastic composite reinforced electric hot-melt belt is a typical multi-layer structure. The plastic belt has a multi-layer reinforced steel mesh interlayer in the middle, and a heated metal mesh is arranged under the surface. The surface of the heating mesh is covered with a plastic film useful for improving the watertightness of the connection and protecting the heating mesh. The pipe connection structure is composed of two layers of steel-plastic composite electric hot melt belt, the inner layer is a connecting belt, and the outer layer is a reinforcing belt.