With the development of science and technology and the advancement of technology in China, China's plastic composite pipes have also developed rapidly, and the quality is also constantly improving. The advantages of steel skeleton plastic composite pipes occupy a major position in the construction, chemical and other industries, steel skeleton plastics. The application range of the composite pipe is relatively wide. The unique advantages of steel skeleton plastic composite pipe determine the main development leader in China's plastic pipe industry. The development of plastic pipes in China is relatively rapid and the quality is relatively high.

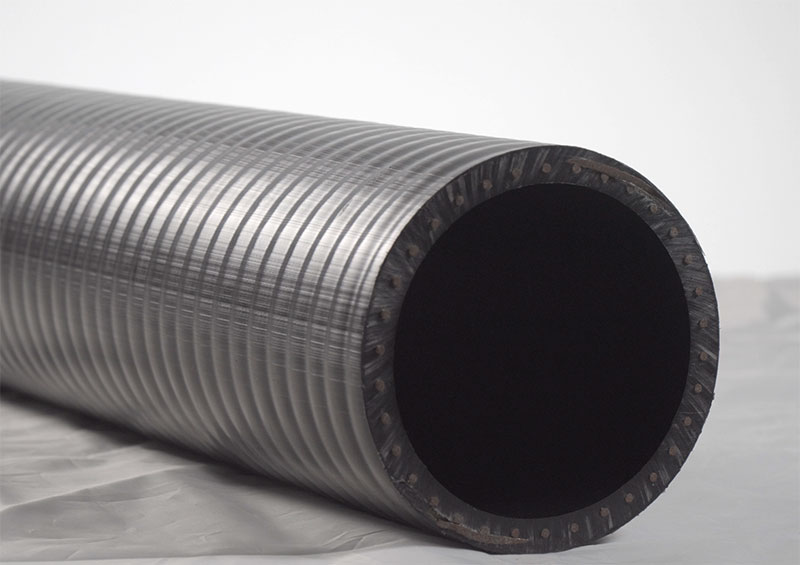

The steel skeleton plastic composite pipe is a steel skeleton as a reinforcement, and a high-density polyethylene continuous matrix. The warp low-carbon steel wire is uniformly distributed in the circumferential direction of the pipe, and the weft wire is wound and welded on the warp wire to form a continuous mesh steel skeleton. The mesh steel skeleton is coated in a polyethylene base material, and is formed at one time, and the structure is compounded uniformly to form an integral body. Its pipe diameter is DN50-800, its withstand pressure is 1.6-3.5MPa, it has flexibility, but also has high strength and rigidity. The pipe connection has two ways of electric coil sleeve connection and flange connection.

Follow the wire mesh skeleton composite pipe manufacturers to understand their characteristics:

1. The inner wall has small smooth conveying resistance and strong anti-fouling ability. When manufacturing steel skeleton plastic composite pipe, the inner and outer setting process is adopted, the inner wall is smoother than the steel pipe, the equivalent absolute roughness is 0.08μm, and the inner surface equivalent absolute roughness of the steel pipe Under the same conditions, the flow rate is more than 3, and the anti-fouling capacity steel pipe is 20 times higher than the steel pipe. It is especially suitable for conveying water medium in hard water areas.

1, good wear resistance

The base material of steel skeleton plastic composite pipe is high-density polyethylene for pipe special, and the wear resistance is 6-7 times that of steel pipe. It has broad application prospects in medicine, petroleum, chemical, coal and other industries.

3, strong corrosion resistance

Since the steel skeleton plastic composite pipe substrate is made of high-density polyethylene, it has excellent corrosion resistance, and has good corrosion resistance to non-strong oxidizing acid, alkali and organic solvent media.

4, double-sided has the same anti-corrosion ability, the inner and outer walls of the pipeline do not need to be treated with anti-corrosion treatment, and the service life is longer than other tubes, especially suitable for municipal buried water supply network, port terminal, airport, power plant, petroleum, chemical industry, Food and other industries.