Today, the polyethylene composite pipe manufacturers discuss with you the details of the pipe flange and flow torque value requirements:

The flange is a part that connects the pipe to the pipe and is connected to the pipe end. There are holes in the flange, the bolts make the two flanges tightly connected, and the flanges are sealed with gaskets. Flange connection refers to the detachable connection of flanges, gaskets and bolts as a set of combined sealing structures. The flange for piping in the pipeline device is called the flange for the pipeline, and the flange is used on the equipment as the inlet and outlet flange of the equipment.

1. Items that must be inspected before installation of the site flange (not limited to):

The fasteners are the correct size.

The material and type of bolts, studs and nuts that match the flange and the condition of the screw holes are good;

Whether the matching parts of the nut and the bolt and the stud are complete;

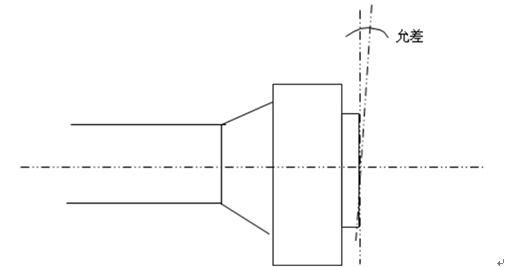

Second, the flange verticality: (the maximum deviation of the seal around)

Diameter ≤ 6′′ (Φ152mm): 1mm,

8′′ (Φ203mm)<diameter≤10′′ (Φ250mm): 1.5mm,

Diameter ≥ 12′′ (Φ300): 2mm

Flange verticality diagram

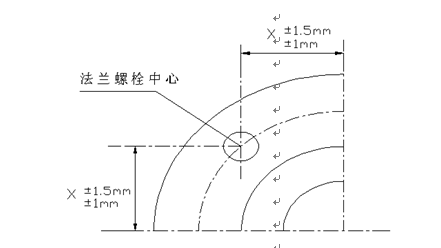

Third, the flange orientation

The distance tolerance between the center of the flange bolt hole and the two perpendicular vertical lines of the flange is:

When the diameter is ≤ 10" (273.1 mm), X ± 1 mm;

When the diameter is >10" (273.1 mm), X ± 1.5 mm.

Flange orientation diagram

Fourth, flange parallelism check

Take four points from the two vertical diameters and measure the size. Parallelism tolerance values are as follows:

1. Use spiral wound metal gasket with a tolerance of 0.2mm;

2. Use other types of gaskets, the tolerance is 0.2mm for pipes with diameter ≤ 3〞, and 0.3mm for pipes with diameter ≥ 4〞 (between two teams of a pair of flanges);

3. The flange to which the pump is connected shall have a general tolerance of 0.1 mm unless otherwise specified by the supplier in the special technical requirements document.

Five, concentricity check

The concentricity of the flange requires that the bolt can be easily inserted back and forth into the flange eyelet by hand without the need for force.

Six, the gap of the flange

Due to the gap caused by the elasticity of the pipe, the stress of the equipment should not exceed the allowable value (see supplier's specifications and drawings);

Make sure that the bolts are tightened without affecting the alignment of the motor and pump. If the alignment is affected, adjust the piping to the flange.

Seven, flange bolt installation inspection

1. Flange tightening torque check

The tightening torque value for the pipe flange (excluding the flow orifice flange) of the nuclear island process system (excluding the SEC system) is determined according to 0126AT4107 "Tightening torque for pipe flange installation".

For the mating flange of the butterfly valve body with sealing surface, refer to the relevant documents of the valve supplier; for the winding gasket purchased by the installation company, refer to the parameters provided by the gasket supplier to determine the torque value; For tightening torque values for connecting flanges on containers, pumps and other auxiliary equipment, see the design data on the equipment drawings.

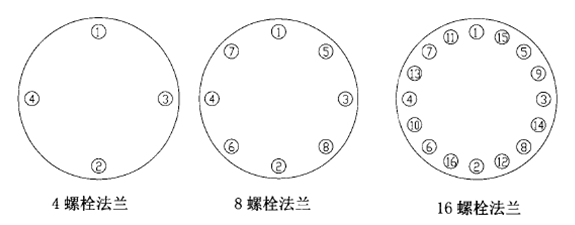

2. Bolt tightening sequence

The bolt tightening sequence is as follows (basic principle: cross symmetry)

The torque must be executed according to a series of procedures. According to the working procedure of the project department "FQQC-WP-3004", the initial torque is 20% of the final torque, and then the torque is 40% of the final torque until the final torque is completed. According to "0426AT4453_BOP pipe flange connection tightening torque program _A_CFC" only three times of torque, the first time is 30% of the final torque, the second time is 60%, the third time to the final torque. After the torque is completed, the bolts must be re-checked in clockwise order.