Hubei Xingxin Technology Co., Ltd. as a steel wire mesh skeleton composite pipe manufacturer got the news:

Recently, the industry standard of "Steel Wire Mesh Plastic (Polyethylene) Composite Pipe" (CJ/T189-2004) passed the appraisal of the Ministry of Construction and was officially implemented on August 1, 2011.

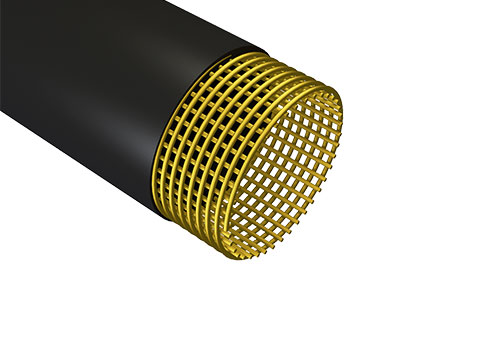

Due to the different structure, the steel mesh skeleton plastic (PE) composite pipe is significantly higher in pressure and pressure resistance than PVC, PE and PP-R pipes. The thickness of the product required to withstand the same pressure is lower than that of pure plastic pipes. The environmental stress cracking, rapid crack growth resistance and creep resistance during pipeline use are improved, and the reliability of long-term use is also guaranteed. The above characteristics of the product make it have broad application prospects in municipal water supply, especially in the pharmaceutical, petroleum and chemical industries. The steel mesh skeleton plastic (PE) composite pipe is a new type of pipe which is formed by a high-strength steel wire which is distributed in the pipe material and which is reinforced by a high-density polyethylene inside and outside. It not only retains the excellent pressure bearing performance of the steel pipe, but also has the good hygienic performance of the plastic pipe and the ease of laying, technical reliability and long service life. The birth of steel mesh skeleton plastic (PE) composite pipe will solve the problem of poor pressure bearing capacity of large diameter plastic pipe.